OIL & GAS, PETROCHEMICAL

Our highly qualified teams, our technically led centers of excellence are experts in helping Oil & Gas and Petrochemical manufactures in new and existing market, with our project delivery experience, we will give you predictable results that meet your business objectives. From the creation of new assets to services that sustain and improve operating assets, we deliver innovative solutions wherever you need us. Showing you how you can convert your strategies in to a sustainable and profitable business. This includes but not limited to: Synthesis Gas based products including Ammonia; Methanol and their derivatives; Ethylene and their derivatives; aromatics; Oxides, Glycol & Polyols and derivatives; Chlor-Alkali, ethylene dichloride, vinyl chloride monomer & Polyvinyl chloride.

We are one of the leading end-to-end engineering company

Feasibility Studies

PMC – Project Management Consultant

OBCE – Open Book Cost Estimate

FEED – Front End Engineering and Design

Detail Engineering

• Extended Basic Engineering

• Stress Analysis

• Technical / HAZOP Studies

• Construction Supervision

• As Built

Procurement Services

Engineering (FEED, Basic Engineering Package & Detailed Engineering Package)

- Civil & Structural Design Basis

- Staad calculation (RCC & Steel structures)

- Standard drawing (civil & structural)

- Structure connection details

- RCC building drawing (layout & details)

- Steel building drawings (layout & details)

- Pipe rack foundation details

- Pipe rack structure details

- Equipment foundation calculations

- Equipment foundation GA & Detail drawing

- Cooling tower foundation GA & Detail drawing

- Tank foundation details drawing

- Dyke wall foundation details drawing

- Underground services system drawings

- Stormwater layout and details

- Plant Road layout and details

- Architectural GA drawing (Plant & non-plant building)

- Bill of Material / Bill of Quantity (RCC & Steel)

![]()

![]()

![]()

![]()

![]()

![]()

- Instrument Index

- System I/O list

- Instrument Datasheet & Specification

- Instrument Cable Schedule

- Instrument Cable Drum Schedule

- Wiring Connection List

- Instrument Loop Diagram

- Instrumentation / Electrical Interface Details

- Process Hook-up Drawing

- Pneumatic Hook-up Drawing

- Analyzer Process Hook-ups

- Instrument Wiring Plan

- Instrument Air Tubing Layout

- Layout of Panel and Equipment in Control Room

- Instrument Air Header Schedule

- Level Sketches

- Junction Box & Instrument Location Layout

- Main Cable Tray Layout

- Typical Installation Drawing

- Material Requisition (Instrument General Requirements)

- Instrumentation BOM

- Technical Bid Evaluation (TBE)

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

- Electrical Design Basis

- Electrical Load List

- Single Line Diagram (SLD)

- Sub Station Layouts

- Data Sheet and specifications for Equipment

- Typical Installation Drawings

- Power Adequacy Report

- Electrical Tie-in list

- Electrical Schematics

- Inter Connection Drawings

- Calculations- Lighting, Earthing, Lightning, Cable sizing, Voltage drop, Cable, UPS etc.

- ETAP studies: (Load Flow study, Short Circuit study, Relay Coordination study, Motor Starting Study, Transient Study Reports)

- Layouts for Cable & Tray routing, Lighting, Earthing, Lightning, Power Installation

- Cable Schedule and MTOs

- Vendor Documentation Review

![]() 3

3

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

![]()

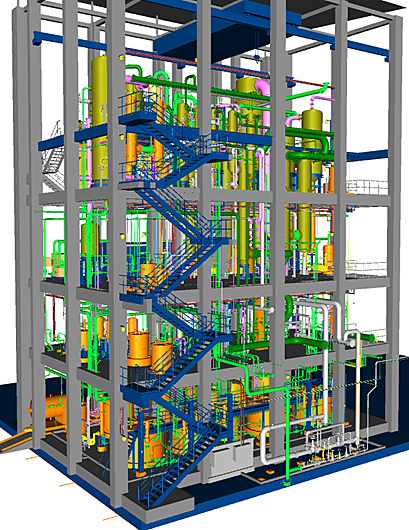

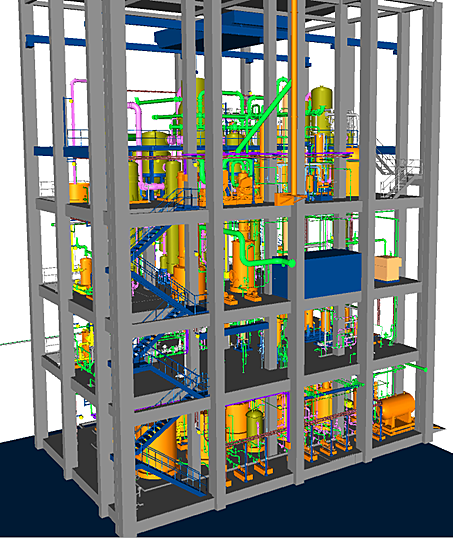

- PROCESS ENGINEERING

- MECHANICAL ENGINEERING

- CIVIL & STRUCTURAL

- PIPING & LAYOUT

- ELECTRICAL ENGINEERING

- INSTRUMENTATION & CONTROL SYSTEM ENGINEERING

TECHNICAL STUDIES

⦁ Dynamic simulation of TV Compressor

⦁ CO2 Compressor Dynamic Simulation

⦁ Dynamic Simulation studies for off-gas compressor

⦁ Process Dynamic Simulation of CO2 Compressor.

⦁ Additional case study for TV Compressor Dynamic simulation

⦁ Dynamic simulation studies for syngas compressor

⦁ Process Dynamic Simulation for ethylene compressor

⦁ Technical study (revamp) of Blow Down Header.

![]()

![]()

⦁ CFD Analysis of Catofin Reactor Air Outlet Header

⦁ CFD Analysis of Air Inlet nozzle with injection Gas Sparger in Catofin Reactor

⦁ ASSP Stack CFD Study

⦁ CFD Analysis of Catofin Reactor Air Outlet Piping Header with baffle plate (Erosion Study)

⦁ CFD Analysis of Air Washing Arrangement (Air Intake Louvers)

![]()

![]()

⦁ Motor Re-Acceleration Study

⦁ Studies for petrochemical plant

⦁ Studies for Phosphate-based fertilizers plant

⦁ 4.16KV Motor Protection Relay in SS#2 and SS#5

![]()

- PROCEED DYNAMIC SIMULATION & ASPEN SIMULATION STUDIES

- COMPUTATIONAL FLOW DYNAMICS (CFD) STUDIES

- E-TAP STUDIES

- HAZOP STUDIES

- AS-BUILT SERVICES

- PROCUREMENT SERVICES (TECHNICAL ASSISTANCE)

PROJECTS LIST (HAZOP STUDY):

Ammonia Nitrate Complex (2021)

STG project, Indorama, (2020)

DAP 1 & 2 Environment Abetment, Indorama, (2019)

Ammonia scrubbing system, Indorama (2019)

Process Air Compressor, India, (2019)

Co2 Compressor system, India (2019)

MTBE/PP/Utilities complex Petrochemical Complex, KSA (2017-18)

Ammonium Nitrate Melt export facility, India (2018)

Co2 / NG Compressor packages, Egypt (2016)

Syngas / Ammonia Compressor packages Tukey (2016)

Food Grade Phosphoric Acid plant, India (2016)

TV Compressor package KOC, Dubai (2016)

Pesticide Complex, India (2015)

Pesticide Complex (Complex-coproduction project), India (2015)

Ammonia Vapor lines modification, India (2015)

Additional Reactor for Methanol Recovery, KSA (2015)

Formaldehyde Derivative Complex, KSA (2015)

Additives Complex, KSA (2014)

Propane Sphere modification, KSA (2012)

![]()

![]()

Brief Description of Process

WNA Plant

Liquid ammonia is taken from storage tanks and vaporized NH3 evaporator and further superheated in a super heater to 80 deg C. Atmospheric air is compressed to 4.5 kg/cm2 and heated to 200 deg centigrade, ammonia vapor and compressed air are mixed and reacted on Pt-Rh catalyst gauzes to form nitric oxide (NO) and it is highly exothermic. The nitric oxide (NO) is further oxidized to nitrogen dioxide and then absorbed in water to form weak nitric acid (of 60% conc.) and it is also exothermic. The heat of oxidation and absorption is removed by generating steam in the waste heat boiler and cooling water/chilled water circulation, respectively. Tail gas coming from the absorption tower contains traces of NOx’s and these are converted into nitrogen and water vapor in a catalytic converter and vented to the atmosphere after recovering energy in a tail gas turbine. Excess steam is exported to the ammonium nitrate plant.

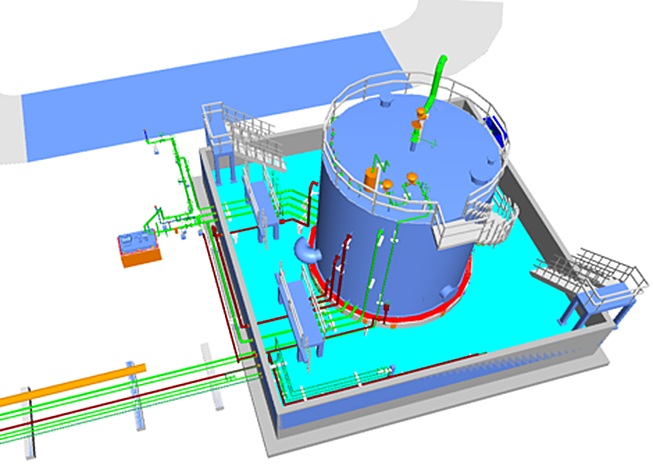

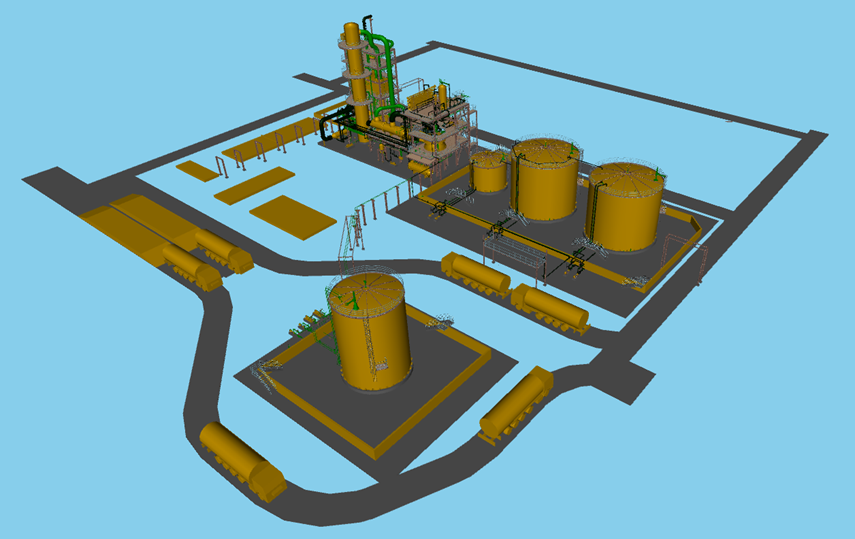

INTRODUCTION

To set up AN Melt storage tank (30 MT), loading and tanker washing facility from AN Melt plant to the customers by road tankers. Provided basic engineering and detailed engineering for this AN melt storage tank and loading facility. This facility mainly consists of a concentration correction tank, AN melt storage tank, tanker loading & washing area, and associated transfer pumps. The original capacity of the plant was 80TPD (100% basis) each and was increased to 100TPD (WNA plant) and 12TPD (AN plant) in the year 2001.

HAZOP Study

The HAZOP study is a qualitative technique that allows the identification and classification of hazardous scenarios in categories of frequency (.e., likelihood), severity and risk in a specific system with their causes and effects. Safeguards already in place to prevent or mitigate the hazards are then evaluated for their adequacy and whenever necessary/advisable, additional measures to reduce the risks are identified. The HAZOP technique also helps in the identification of situations where plant operability could be compromised.

A total 72 recommendations are proposed for implementation after the HAZOP sessions, and these are recorded in the HAZOP list of recommendations (Annexure D) along with the agency responsible for implementation. The number of recommendations under High Risk (HR), Medium Risk (MR), and Low Risk (LR) are:

SCOPE & OBJECTIVES

The scope of HAZOP study includes the main plants WNA & AN plant along with other utilities like service boiler unit, ammonia (NH3) storage unit and bagging unit. The scope is clearly marked in the P&IDs.

The objectives of the HAZOP study are as follows:

To identify possible deviations from the design intent.

Identify potential hazards and operability problems associated with the deviations.

Review the safeguards provided in the system and their adequacy and recommend additional safeguards, if any.

Recommend actions to eliminate/mitigate the identified hazards and/or operability problems or to identify areas that need to be further investigated.

![]()

![]()

HAZOP PROCESS

The HAZOP Study is a systematic analysis of the Design made through a review of the Piping and Instrumentation Diagrams (P&IDs), developed in order to assess the possible hazards and the operability issues of the system. The methodology relies on a series of guidewords that are applied to each “Node” to identify process deviations and to investigate their impact on Safety and Operability performances. A summary flow chart of the HAZOP process is shown in Figure 6.1

HAZOP WORKSHEETS

The HAZOP worksheet is the findings of the minutes of meeting which provides systematically the logical process and conclusions carried out during the analysis. Worksheets keep accurate record of each situation discovered, either it is potentially hazardous, or impairing plant operations, or jeopardizing equipment integrity or plant operators’ safety.

The HAZOP analysis has been recorded in the Microsoft Excel worksheets. A typical worksheet is composed of the following fields, as shown in Table 6.2. However, the work sheet in the HAZOP

![]()

![]()

![]()

![]()

![]()

![]()

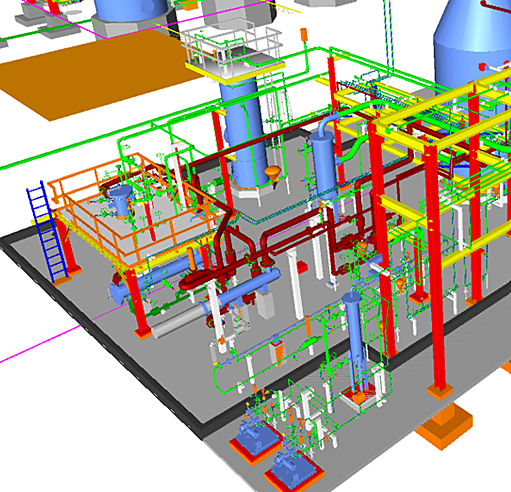

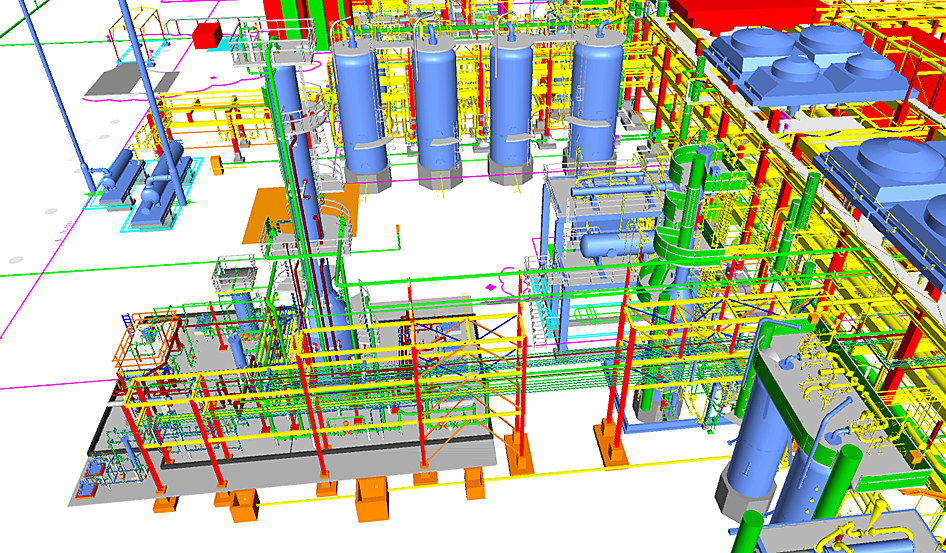

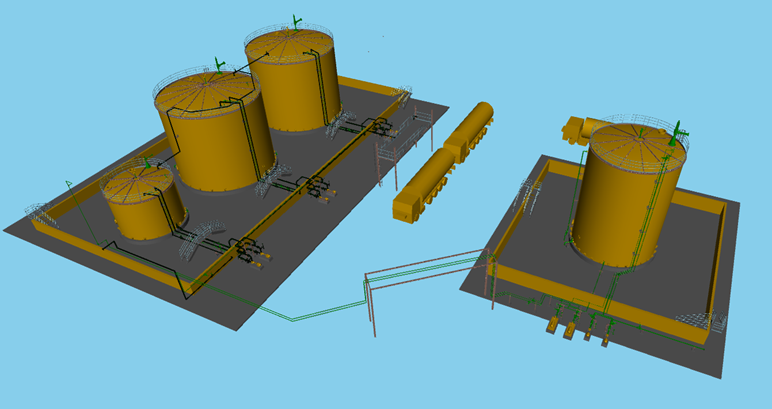

The following activities will be involved in As-Built services for all engineering disciplines.

- Red marks ups updation as per construction changes in all documents and drawings

- Preparation documents / drawings as per of existing plant details.

- Conversion of Hard copies into Native files (docs / drawings)

- 3D Model preparation as per hard copies / plant details

LIST OF SOFTWARE:

- AVEVA E3D – 3D MODELLING

- Auto Plant 3D – 3D MODELLING

- CAESAR II – PIPING STRESS ANALYSIS

- STADDPRO – STRUCURAL ANALYSIS AND DESIGN

- HYSYS – PROCESS SIMULATION

- HTRI – THERMAL DESIGN

- ANSYS – ENGINEERING SIMULATION SOFTWARE

- PV ELITE – PRESSURE VESSEL DESIGN

- ETAP – ELECTRICAL POWER SYSTEM ANALYSIS

- AUTOCAD – 2D DRAFTING

- MICROSTATION – 2D DRAFTING

- PRIMAVERA & MS-PROJECT – PROJECT SCHEDULE

- MS-VISIO

![]()

![]()

![]()

![]()

Following activities will be involved in procurement services in consultation with technical team.

- Material Requisition (MR)

- MR Review by Client / Consultant

- RFQ issued to Vendors (Approved Vendor List)

- Review of vendor technical proposal

- Technical Clarifications Lists (TCL)

- Technical Bid Evaluation Table (TBET)) as per vendor proposal & clarifications

- Follow-up to get the Priced and Un-priced Bids in sealed covers

- Purchase Requisition (PR) inputs to Client / Consultant

- Placement of equipment order on selected vendor assistance

- Vendor Documentation Review for equipment (static / rotating / package)

![]()

⦁ DPR for Customized Fertilizer Plant

⦁ Due diligence for acquisition of Ammonia/Urea/HNO3/AN complex

⦁ Due Diligence for acquisition of a Soda Ash Plant

⦁ Relocation of Ammonia and Urea plant

FEASIBILITY & TECHNICAL STUDIES: PROJECTS LIST

⦁ Feasibility study for 50 TPD ABC Plant

⦁ FEA Analysis for Pulverized motor failure in DAP plant

⦁ Constructability review for SAP-1, SAP-2 and STG revamp

⦁ Process Dynamic Simulation of CO2 Compressors for Urea plant

⦁ Pre-feasibility and feasibility studies for soda ash, sodium bi-carbonate edible salt, HCL and caustic soda plant

⦁ RCA for ammonia scrubber fan failure in DAP plant

⦁ Constructability study for Boiler/STG project

⦁ Deaerator and PGD vessel studies

⦁ Assessment study of Ammonia urea complex of PIC

⦁ Process Dynamic Simulation of compressor system

⦁ Ammonia/urea plant upgrade feasibility study

⦁ Plant integrity studies for buildings and structures

⦁ Vibration studies of piping & structures

⦁ Stress & Dynamic Analysis of critical piping

⦁ FEA studies and design of Pressure Vessel

⦁ MTO for fertilizer complex for open book estimates

⦁ Feasibility study for ammonia plant revamp

⦁ Ammonia plant relocation feasibility study